Incredible Deal - LIGHTLY USED - Only 1 Year Old

Selling Printer & Applicator for $16,995 - (New units sell for $25,495)

Selling GeoKnight Press for $695 - (New is $1,650)

[CENTER]***LOCAL PICKUP ONLY***

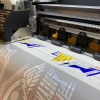

ColDesi DTF 24H2 Printer / Powder Applicator and Heater - $16,995

This printer has always produced incredible transfers and has been meticulously maintained by me personally.

Package includes:

- DTF 24H2 Printer

- Powder Applicator and Dryer

- DTF Print Optimizer V2 Keyless Software

Direct to film is the best way to produce high-volume custom transfers for apparel. Especially custom t-shirts.

High Volume is redefined when you’re talking DTF. Produce hundreds of different graphics/sizes in one run!

The DTF-24H2 produces brilliant digital transfer sheets, handling everything from single color shirt labels to left chest logos to full-size prints. The DTF printer uses PET transfer film which is translucent so you can see the design underneath the film when you later heat-press it onto the garment. The PET film has a thickness of around 0.75mm which allows for better transfer characteristics.

You can produce brilliant full-color prints:

- On Virtually Any Garment

- In Virtually Any Placement

- Around 10 Seconds Press Time

- Through dozens of wash cycles

High Quality Commercial Printheads:

The 24H2 is a 24″ DTF printer that has a dual print head design that lays down the colors in a blend of CMYK colors with the first printhead, and then lays down the perfect amount of white underbase on top of the colors in perfect alignment so that you do not have any white peeking out. The alignment is on the film, rather than on the bumpy fabric of the shirts so it creates a crisp design edge that you can’t even get with traditional screen printing.

Includes Print Optimizer RIP Software:

As part of a Digital HeatFX system, which includes the Print Optimizer software, you will have ultimate control over the ink laydown. If you are doing blended gradients you can dial in the color accuracy on a per-channel basis. If you are doing single color logos on white shirts, you can dial down the ink flow and put just the right amount of ink to make the shirt pop without ink waste.

ColDesi Direct to Film printers also have a heated print path that begins the drying process immediately after the print. The white ink layer on top will become dry to the touch-ready to receive the specialized powder adhesive coating.

Powder Applicator and Dryer:

The automated and adjustable powder shaker keeps a consistent flow of powder that applies to your prints. Excess powder then falls to the catch tray underneath so the powder can be reused. Never any waste!

The built in powder clear ensures excess powder falls away from the transfer before entering the heater.

Adjust the speed and temperature of the heaters conveyor belt to customize the drying process. The built in vacuum keeps the film firmly in place on the conveyor belt while passing through.

It’s the unique powder adhesive coating that gives DTF prints their signature soft touch. Instead of thick transfer films, or vinyl’s, the Direct to Film Process has only two ingredients. The ink, and a thin coating of powered adhesive.

The soft hand of DTF is holy grail of custom apparel. It’s never been possible to get the incredible soft feel of half-tone screen printing in a transfer process. But with DTF, you get all that and more.

The DTF powder adhesive is moisture-seeking, so it draws itself into the ink of the print and chemically bonds to form a strong permanent adhesive that sticks extremely strong to both cotton and polyester fibers.

Take-up Reel:

The included electric take up reel keeps your transfers organized while printing so you don't have to worry about the film falling to the ground. Tensioned perfectly to roll up your film without pulling too hard.

Machine Specifications:

Overall Dimensions - 131” x 67.5”

2 Head Printer – 37″ x 67.5″ – 330 lbs – powered by directly plugging into shaker/dryer - 110V - 10 Amps

Shaker/Dryer – 76" x 38" - 440 Pounds - 220V - 20 Amps Single Phase

Environmental Conditions – Your printer should only be used in a dust-free, clean environment. Humidity and temperature need to be at moderate levels for optimal printing. Manufacturer recommendations for optimal operational temperature & humidity are as follows: 60°F – 80°F and 50% – 70% relative humidity.

Both the printer and shaker/dryer are on casters and can easily be moved.

Software – To operate Digital Heat FX Print Optimizer with the DTF-24H2 printer, a dedicated Windows 10 PC (or greater) with an Ethernet connection is required. For best results, the PC should have a minimum of 32GB RAM and a 500GB solid-state hard drive. Due to the printer not being networkable, for networking or internet access, WiFi capabilities are necessary.

Overall, this printer is my favorite I have ever used. The graphic images are crystal clear and the press is fast. I used to have a DTG G4 and I'm able to make 100 shirts in a quarter of the time now. The only reason I am selling is because we are moving and I won't have a space for it.

---------------------------------------------------------------------

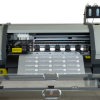

Geo Knight DK20A 16" x 20" Clam Auto-Open Heat Press - $695

***You can purchase press on it's own***

This press is 3 years old and is in perfect working condition. I just replaced the gas shocks a month ago. There was a small metal piece that broke off on the top that guided the magnet but that happened in the first two months of owning it and has not had any effect on functionality.

The DK20A is the AUTO-RELEASE "Pop-Up" version of Geo Knight's largest manual clamshell. This amazing high-tech feature makes your Digital Knight clamshell act like a semi-automatic, air operated press, without the compressor! Simply close the press as you normally do, and at the end of the digital timing cycle the press releases automatically.

The Auto-Release upgrade also features the "HOVER" feature. This means when the handle is lowered without fully clamping the machine, the press will hover over the work, usually needed for curing purposes. At the end of the time cycle, the press releases automatically as usual.

The DK20A 16x20 clamshell press opens for full access to the lower bottom table. It is important to note that the back of the heat platen raises above and away from the bottom table, providing better access than other clamshell presses. The frame support allows operators to slide shirts over the table with complete drape space around and underneath the loading area. Interchangeable bottom tables for smaller pressing areas are available. This press is ideal for environments with space limitations, and for users who need more portability and mobility than the over-weight swing away presses.

Specifications:

Weight: 103 Lbs

Electrical: 1800W / 15A / 110V

Dimensions: 36"L x 17"W x 16"H

***Serious inquiries only please - Local pickup only***