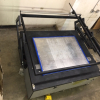

The press is a TMI Jaguar parallel lift one armed screen printing press. The printable area is 48"x36". The footprint is 67"x78" with the lift down, and 67"x97" with it up.

It's a spring assisted lift, not pneumatic. Very simple machine. We added a vacuum gauge so you can see how much vacuum you're pulling, put a quieter vacuum motor in it, and hired a machinist to rebuild the platen with a heavier and thicker piece of aluminum to be VERY flat. New it was $12,500, never mind the cost of what we did to it.

I am throwing in 3 large format Newman retensionable frames to sweeten the deal. They max out the printable area of the platen. These were $760 EACH new. It will also come with the long arm wrench needed to tighten the frames as well as a tensiometer. The wrench was somewhere around $500, and the extra head for it was around $250 new. I forget how much the tensiomenter was. The only tool you will need to provide is a torque wrench, which is like $100 if you get it from someone other than Newman.

The following is the info on those frames from Newman:

Model/Size: M3I1N-UL 51.5" x 63.5" OD (46" x 58" ID)

Frame profile: 1 5/8"H x 2 3/4"W

Weight: 26 lbs (approximate)

It will also come with 2 or 3 of the 18"x20" MZX frames standard size Newman roller frames and the head for the big tensioning wrench for those as well. Sorry I can't remember if it's 2 or 3. It's all in storage.

Believe the hype. Having the ability to raise the tension on screens this big is a game changer.

Asking $9,000 obo

It's already a great deal.

It is all currently in storage at Shamrock in San Francisco. It is a full service crate storage facility with a forklift and a loading dock, so all you'll need is a truck suitable for unloading it into your own space, or a freight service if you are not local.