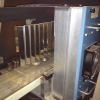

For sale is a bottle cylinder printing system which includes a bottle screen printer and UV dryer curer.

1. Dubuit D-150/American AM-180 Bottle/Cylinder screen printer. ($8500)

2. Dependable Machine Spin Cure with American Ultraviolet UV curer dryer.($8500)

$15,000 together.

Crating is $150 per unit. Will discount if purchased together. Buyer pays shipping.

BOTTLE PRINTER:

This is rebuilt into like new condition bottle screen printer by Ragland Specialty Printing Services. There is a lot done during the rebuild (see below) This unit was never used after the rebuild and is ready to go. I did add some squeegees and some squeegee holders which are included. Has air inflation nozzle as part of the printing assembly.

It comes with two sets of tooling for some bottles (750mL and 100mL). Most likely they will not work for your application. Can print up 1000-1200 parts/hr.

UV SPIN CURE

This unit has a about a 10 foot conveyer with a spinning system to cure 360 degrees around a bottle. The UV unit is made by American Ultraviolet and has a 6" cure zone lamp. The speed of the conveyer and spinner can be sped up or slowed down according to application. It can cure up to 6" wide and 12" tall. It can easily keep up with the bottle printer.

It is used but works great. Used spin cure style bottle dryers curers are hard to find and new ones cost $15K-$30K easily.

Comes with extra lamp. See the video below.

Can send more pictures upon request.

Dependable Machine UV Spin Bottle Curer/Dryer for Bottle Printing - YouTube

PRINTER INFO******************

Hood with locking doors, heavy duty foot pedal with heavy duty safety cover, new bearings, new wear guides, new shafts, new cam, new multi-color registration D.C. motor with three adjustment plates and new Minerk speed controller with forward/reverse/brake-jog/LED green light, off/on switch and variable speed knob, new high intake pressure air regulator, new low pressure air inflation pressure regulator, new air filter and new automatic dump water strainer.

RE-BUILT: run/stop/jog/switches with push/pull emergency stop button, 240 V 3 ph main drive motor with variable-speed clutch pulley, motor reducer, 240 V. 3 ph. electrical starter, micro-adjustable squeegee head, screen arms, nose-cone/air cylinder with Y-bracket with T-bolt and winged-bearing holder and adjustable gear rack. The press is also equipped with heavy duty caster wheels and leveling bolts.

TOOLING: Y-bracket with T-bolt, 14 mm winged bearing holder, 14 mm front ard shaft, base-cup pulley bearing, 6" rear 15 mm shaft extension with locking collar, rear winged support bearing with adjustable aluminum support plate

There are 13 Comments

Re: Bottle Cylinder Screen Printing System

I am looking for a screen printer to print flat plastic sheets, the largest size is 5" x 7".

This machine must have a rotating table, UV cure and automatic takeoff.

I can be reached at 404 610 7962 or email: wlewisatl@hotmail.com If you have anything of this sort or similar contact me. Wilber

Re: Bottle Cylinder Screen Printing System

super cool wish i had a use for it

Re: Bottle Cylinder Screen Printing System

what is the max stroke length and screen width?

Re: Bottle Cylinder Screen Printing System

Thanks for the question.

The max stroke is 14". The depth is about 12"

It can hold a screen to match the stroke. However, the screen holder could hold a screen to almost the width of the machine.

Re: Bottle Cylinder Screen Printing System

Can the bottle printer print on oval shaped bottles? Is there special tooling required?

Re: Bottle Cylinder Screen Printing System

Thank you for the question.

Yes it can do oval shaped products and yes it does require tooling, about $500. I have contact information for someone who could help with the tooling.

Thanks!

Re: Bottle Cylinder Screen Printing System

Still for sale!

Price drop!

$13,500 for both!

Re: Bottle Cylinder Screen Printing System

Posted on Ebay. Here are the auction numbers:

150758236766

150758243512

Re: Bottle Cylinder Screen Printing System

UV Dryer is SOLD!!

Re: Bottle Cylinder Screen Printing System

Bottle printer still for sale!!

Re: Bottle Cylinder Screen Printing System

Printer is Sold!!!