Want to talk about an OMFG! Look at the fist pic below, I removed the cover over the bulbs and the fist thing I see is black spots on the heat shields. Yep that is insulation burning off the wires feeding the cooling fans. I dont know the amps running to those fans but damn if an accident is not inevitable!

Pic 2 below

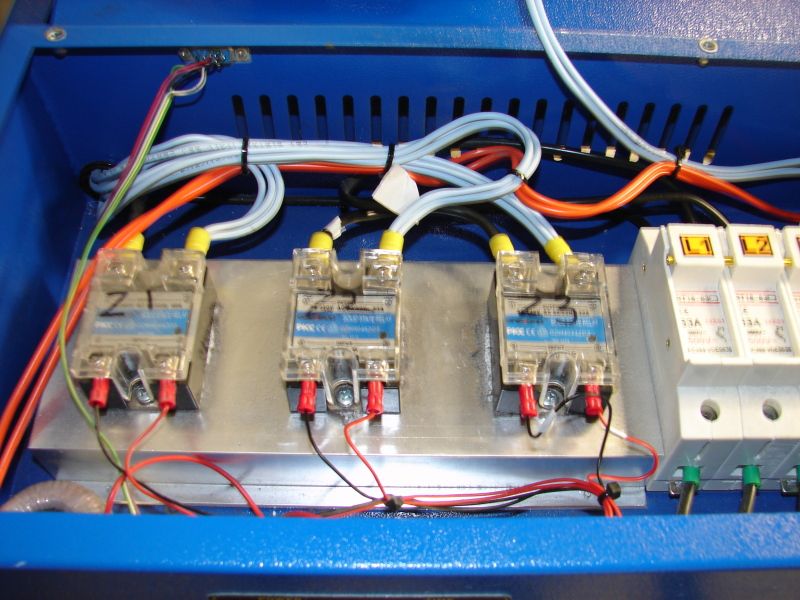

As you can see I traced the wires and marked each SSR to which zone it is. Surprisingly it is a ten bulb flash so the middle (zone2) is actually wired for four bulbs and the other two for 3 each.

Pic 3 below

I first purposely scorched a shirt so the pattern can be seen notice the last third of the shirt is where the major scorching starts. Also please keep in mind I have the flash shimmed 1/4" higher at the end in an attempt to control this.

Pic 4 below

First I swapped the control wires from zone 3 to zone 2 SSR respectively. Re scorched a shirt as you can see identical pattern.

Pic 5 below

I put the control wires back respectively, I then switched the output wires to the bulbs again with zone 2 and zone 3, I would have preferred zone 1 and zone 3 but the wires were to short. Anyways looking at the pic below I think tho it is not easy to discern that there is a difference, you guys can chime in and let me know.

To sum up it may appear to be a funky SSR ( I hope) The controller is definetaly ruled out I would say.

As for the wires burning up under the hood what the hell am I going to do about that? Brian what is the specs on these wires as in voltage and amps, is it dangerous?

Should I look for high temp wire to replace with or is there a high temp insulation I can wrap them in?

Re: Flash diagnosing update

Not as big as yours obviously

Re: Flash diagnosing update

Mike ...The relay we sent is an italian relay and will probably last longer than the ones that are in there now ... since it is a total over kill type device ... please put it on the zone with the 4 bulbs (you may have done it already) no sure :-)

Also ... are you saying that you bought new fans already or just replaced one ???

Reason I am asking is I want to have the best chance of success on this test so we can figure out what is /was happening (removing variables) ...

Note: Please let WebgURL know whether to send1 or 2 ... but we need to have both grainger fans installed for our actual production run to be certain

Mike ... sorry you are having a problem -but- it feels like we might have made some progress (on many levels) thank you for taking the time to post all this stuff ... altough it means you are now a pawn star LOL

Re: Flash diagnosing update

RWB has a small spider squeegee LOL

Re: Flash diagnosing update

I think it is sticky feeling because it is silicon

Re: Flash diagnosing update

If my memory serves me right I changed two if not all of the fans on that flash at the instal.

Owner/Operator of Middletownink

Re: Flash diagnosing update

I replaced it in zone three, I got it in UPS before I seen your post. have to wait till tomorrow to swap it again since I had to let the guys get printing, they were not happy waiting on me all morning lol.

What I mean by the fan is I had one crap out but when looking and messing with the wire feeds it started to work again, so currently all four fans are spinning. Is that cool or do you think replacing is still necessary?

P.S. I do think the relay has helped but I cannot guarantee it till we get involved in a decent sized poly order that requires a full flash. But there is one for this week.

Robert I rechecked the flash height like I told Brian 2" on the front and 2.25" at the rear, I cant raise it any higher because the casing is hitting the bottom of the s/fb assembly.

Re: Flash diagnosing update

More spastic than normal today? No meds or on the drink?

Re: Flash diagnosing update

I think you bought a bunch from Grainger on the RockChick install to replace all on one of here flashes so they were of the same brand ... don't think you bought any at inkman's install ... you had your own Printex Group credit card at that time so it shouldn't be to hard to have Colleen go back and check the Printex bank statements if inkman is unsure :rolleyes:

Re: Flash diagnosing update

I am typing on my Samsung so I just replied within your quoted post ...

if you had the longer stroke that wouldn't be the case

Re: Flash diagnosing update

actually ... Mustang Printers secured Round #1 financing for an Inventory Investment Program ... so I just got back from a long trip over the weekend ... spent some awwwwesome time with the kids -then- took a freakin' nap this afternoon ... I have to go assist Mustang Printers tomorrow with a potential client ... don't tell M&R (cuz these guys have several M&R presses) the tide for Mustang is really shifting now ... ever since all this Forum nonsense people are coming out of the wood work with support ... HATERs = HELPers :p

Re: Flash diagnosing update

What are you doing to correct that?

Brandt

Graphic Disorder

http://www.graphicdisorder.com

Add us on facebook:

Brandt: http://www.facebook.com/graphicdisorder

Graphic Disorder:

http://www.facebook.graphicdisorder.com

Re: Flash diagnosing update

You win Barnes, the world is yours.

Re: Flash diagnosing update

Thanks brother ... I gotta admit ... I got it pretty good ... tucked in my little ones last night and read them a story ... Life is Good !!!

Take care brother ... let me know if you can make it to an upcoming Mustang install ... there is one in New Orleans and another in Columbia, Missouri ... both are 12 color with Servo Lift ... join us :)

Re: Flash diagnosing update

GraphicDisorder ... please take your HATE to another thread ... if there is any sincerity in your question (which is doubtful) feel free to start a new thread on the topic (Spiderman out)

Re: Flash diagnosing update

No hate here, that was as straight forward a question as one can ask.

Brandt

Graphic Disorder

http://www.graphicdisorder.com

Add us on facebook:

Brandt: http://www.facebook.com/graphicdisorder

Graphic Disorder:

http://www.facebook.graphicdisorder.com

Re: Flash diagnosing update

Oh I see it... everyone be still and quite and look:

"you don't need a hook for the worms to dance."

Re: Flash diagnosing update

*quiet

Damn my fingers!

"you don't need a hook for the worms to dance."

Re: Flash diagnosing update

Awesome ... start a new thread :)

Re: Flash diagnosing update

I am pretty sure my press will never have longer heads I gave up hoping on that a long time ago.

Re: Flash diagnosing update

These pics are from musterdbom ...

Re: Flash diagnosing update

Musterdbom bought a pot from them as well ...

.

Re: Flash diagnosing update

Note: musterdbom is like 9 feet tall LOL

Re: Flash diagnosing update

Lets tackle one issue at a time ... otherwise we might get back into face punch mode :eek:

we ordered the fans ... will email you when I get the tracking number

Re: Flash diagnosing update

I may be out to lunch, but wouldn't 4 bulbs wired in parallel run hotter than 3 in parallel?

Re: Flash diagnosing update

Ink... it shouldn't.

Every bulb in your house is wired in parallel. They don't burn any hotter. They draw the current they need to. If anything if the current was restricted they would burn lower due to less juice to supply to each of them. More load.

Batteries in Series cause this to be true but that isn't the case here.

"you don't need a hook for the worms to dance."

Re: Flash diagnosing update

4 bulbs in series between two legs of 3-phase will create a lower resistance circuit than 3 bulbs between two other legs of three phase. But I'm probably barking up the wrong tree on this one.....

I also would have concerns of the SSR's ability to switch as quickly as required for PWM switching for bulb intensity control if that's what they are using. A tiny bit of switching lag would easily cause one bank of bulbs to run hotter.

You might need matched relays for the flash to operate evenly as switching speed would need to be virtually identical or you're in trouble.

Are other companies using this type of control circuit to attenuate bulb temp?

Re: Flash diagnosing update

Re: Flash diagnosing update

Actually Rich you do use this technology on your higher end flashes ... you may want to check your statement ... Mariusz laid it into the circuit years ago (back when your flashes were blue) ... I will extend you a professional courtesy (toclarify your position)

Re: Flash diagnosing update

Here is a hint 244

http://ccipower.com/products/controllers/1021a

Re: Flash diagnosing update

Re: Flash diagnosing update

I guess you are right ... that board in the pics must be a copy of the M&R board in Cayenne LOL

When will you be filing a Federal Lawsuit against them :eek:

Re: Flash diagnosing update

All right now I went ahead and did what you said this morning Robert, I placed the new SSR in the zone with four bulbs. Ran all day then bang see pic below. The thing looked like an arc welder when it went.

Re: Flash diagnosing update

SEXY ... check the rest of them as well ... also ... did the new fans come in :-?

Note: this is for all folks reading ... its a good idea to spin your bulbs periodically to scuff the contacts ... especially if you run discharge, waterbase, solvents, etc. and clean your fans/vents/filters !!!

Re: Flash diagnosing update

Make sure you guys keep the electronics Lint/fuzz feee !!!

Re: Flash diagnosing update

Re: Flash diagnosing update

Do you need tomsell bulbs that bad LOL

Go clean your flash cures 244 :D

Re: Flash diagnosing update

Uh what does that have to do with my bulb all of a sudden burning out?

Re: Flash diagnosing update

People are kidding themselves if you that think he would EVER stay on topic a full thread with our without outside "mucking".

Brandt

Graphic Disorder

http://www.graphicdisorder.com

Add us on facebook:

Brandt: http://www.facebook.com/graphicdisorder

Graphic Disorder:

http://www.facebook.graphicdisorder.com

Re: Flash diagnosing update

Have you tried swapping around the incoming legs of power yet? Or easier yet, verifying with a multimeter that each leg is delivering exactly the same voltage while loaded and unloaded?

Re: Flash diagnosing update

Please let me know the following:

Re: Flash diagnosing update

No fans yet

Socket looks pristine.

Spare bulb uh not!

The only connection i can draw here is the SSR I swapped to that zone today. It happened exactly as the flash turned on, bright like an arc welder.

Re: Flash diagnosing update

The easiest and best fix would be to throw that thing in the trash and buy one from M&R or pick up a used one. We run older Omni Flashes and guess what....No problems. They run 10 hours a day everyday and just work.

How many more shirts, print time, re-setting up jobs will you have to do before you are at the cost of another flash from someone else?

Re: Flash diagnosing update

Its usually a loose connection or a bulb thats not seated well. You will find the silver at the contact on the bulb melted, usually welds it self onto the end of the pin. Look at each end of the bulb, bet one end still has the silver slug, other missing and black. Happened to me three times and I end up changing the pin socket assm each time. Its cool seeing the sparks, usually someone in the shop screems and jumps. It sucks that the sparks usually put some burn marks on the shirt. To finish the job Ill just run slower with out the bulb then fix it at night when everyone goes home.

Owner/Operator of Middletownink

Re: Flash diagnosing update

Brian's right on this one for sure ... sparky ... sparky ... I had a dog named Sparky when I was a kid -and- I grew up on Edward Street ... hence my p o r n name is Sparky Edwards

As for the bulb ... well nobody warranties them (not even 244 the Screen Print Jesus)

Soneko has them though ... I miss that little dog :(

Re: Flash diagnosing update

Here is the Soneko website (this is where M&R buys their bulbs) Soneko.com

They sell the sockets as well ...

Re: Flash diagnosing update

Never mind Brian i will just reroute wires to the outside should be easy enough.

Re: Flash diagnosing update

1 amp fuse protecting the fans

How high is the flash from pallet. I have the bulbs 2-1/2" above the pallets. Is yours to close?

Owner/Operator of Middletownink

Re: Flash diagnosing update

2" at the head 2.25" at the tail, I could but it up some.

Re: Flash diagnosing update

...and there you have "Best Price".

LOL

Brandt

Graphic Disorder

http://www.graphicdisorder.com

Add us on facebook:

Brandt: http://www.facebook.com/graphicdisorder

Graphic Disorder:

http://www.facebook.graphicdisorder.com

Re: Flash diagnosing update

And there you go $hitting on this man's thread where he is trying to diagnose a problem.

Please don't bother replying on this thread I won't take it any lower. You can PM me if you want to discuss it.

"you don't need a hook for the worms to dance."

Pages